Articles and News

NO GLASSES NEEDED: THE WONDER OF 3-D PRINTERS | November 15, 2012 (0 comments)

Merrick, NY--What would you--could you--do with a printer that can turn out small objects in three dimensions? Objects like boxes. Or small toys. Tools. Parts. A miniature Eiffel Tower. Even a new beak for a bald eagle. Or perhaps an action figure that looks just like you, but smaller, and wearing no jewelry (yes, there are limits). And, of course, models for jewelry. But really, who wouldn't want their own action figure?

3D printing isn't new, and it has been in use in the jewelry industry for some time. Many of your suppliers already use 3D printing in conjunction with CAD (computer aided design) to design and create the jewelry that's in your showcases.

Early examples occurred during the 1980s on expensive equipment that was physically large and limited as to what could be printed; therefore they generally were used by large companies for manufacturing applications. But today the newer 3D printers are made for personal use. It's now entirely possible for a home office or a jewelry store to have a 3D printer sitting next to an ink jet printer--in many cases for an investment of only a few thousand dollars.

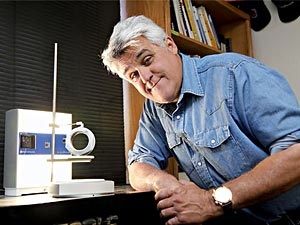

At first thought, it's a bit mind boggling. Moving from two dimensions to three in a desktop printer--or replicator, as MakerBot calls their latest version--opens up an entire new way of thinking. Star Trek aficionados will note that it's similar to the replicator on the fictional Enterprise, but back on earth, entertainer Jay Leno uses his to recreate old engine parts for his auto collection. NASA uses theirs for rocket components. Parents can use it to create toys for their kids. Manufacturers of all sorts use the technology for prototyping new designs. Your dentist may use it to make crowns or plastic alignment trays for your teeth.

Comedian Jay Leno and a part he made with his 3-D printer. Image: Popular Mechanics.

Commercial 3D printing prints with mostly metals and plastics for now, with more choices soon to be available. Those new 'inks' range from wood pulp to sugar to cupcake icing, and will likely include electric circuits, opening up a whole new method to create electronics from scratch.

The printing process can take a while, sometimes hours, depending on how intricate the object is. It uses an 'additive' technology, building the objects layer by layer from the bottom up. If you're short on inspiration, you can always download one of thousands of designs, many free, to be printed. (Note: familiarity with CAD is enormously helpful if you're not going to download a pre-made design.)

But what about jewelry applications? Yes, the new personal 3D printers probably can make jewelry out of whatever their 'ink' choice is, but there are likely finishing and resolution issues, making it more suitable today for non-inventory purposes.

"With direct metal printing of precious metals, finishing is an issue, although it's appropriate to some things," says Eric Alulis of Philadelphia, PA-based manufacturer SuperFit. But he thinks those issues will be resolved within five or 10 years.

Steven Adler at A3DM Technologies in Portland, OR says there are a good number of designers today using CAD and 3D printers for custom jewelry. He estimates there are conservatively 4,000-5,000 users of the technology in the U.S. jewelry industry. But he cautions that you can't just buy a 3-D printer and rig it up. "Without CAD for jewelry as a starting point, you can't do anything with 3D printers," said Adler, but he advocates jewelers learn CAD. "Millennials and consumers today want something unique," he says. To that end, retailers and designers are serving that market using these technologies for custom jewelry manufacturing."

While 3D printing is mainstream in manufacturing, allowing this new technology into the hands of individuals is bound to lead into various creative places. It's being compared to how desktop publishing changed when appropriate software became readily available and widespread.

Retailers are also getting in on 3D printing at the store level. Retailer/designer Barry Peterson of Barry Peterson Jewelers, Ketchum, ID, has recently taken training for a 3D printer and expects to be using one in his store soon. "We'd like to be completely self-sufficient," said Peterson. "I can avoid the service bureau when I need something printed by having a 3D printer onsite."

To get a closer look at how this technology works, your favorite supplier might be a great place to visit. Or, if you are in New York City, you can always visit a 3D printer/replicator retail store in NYC and check out the personal 3D printer in action.

Top image: "Thorn Dice" set, made by Chuck Stover. Image: Wired.com.